Creating New

Perfect Smiles

Everyday

Promote, Restore, And Maintain Your Oral Health

Official Partner By

Fast monolithic predictable

Digital Denture is a complete manufacturing process for the rapid digital production of removable full-arch dentures. This innovative process integrates the treatment steps in the dental practice with the digital manufacturing processes in the lab. Exclusive design software and ideally coordinated materials, combined with well-designed manufacturing strategies and the cutting-edge PrograMill milling equipment platform, provide predictable and reproducible results

Fast

With Digital Denture, the new digital manufacturing process for dentures, you save valuable time compared to manual production methods: fewer manual working steps, fewer interruptions in production, no complex plaster models and no articulating. In addition, you benefit from faster model analysis, a quicker set-up in the software, and faster gingiva design and completion.

Monolithic

Industrially manufactured monolithic discs offer many processing advantages and deliver consistently high material quality:

- No polymerization shrinkage

- No thermal influence on the base materials

Predictable

Predictability means certainty of results — an important aspect, in order to be able to work effectively and respond to patient needs. With Digital Denture, all steps are defined and perfectly coordinated. The users are guided through the entire process. This leads to greater processing safety, plannable and predictable results and standardized quality and ultimately satisfied patients.

Dental Zorg

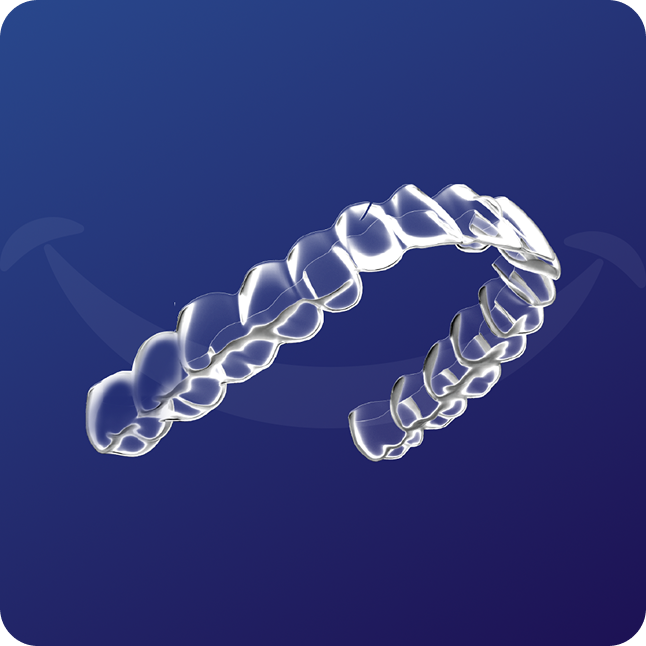

AlignersInvisible Braces

Get straighter teeth in a discreet way with transparent aligners.

Emergency 24h:

Transparent and

Removable

On Average within

4 to 9 Months

Choose to Pay in one

go or Pay Monthly

Aligners are thin

Clear Braces

They are virtually invisible. You wear them 22 hours a day to exert sufficient pressure on your teeth. You take them out when you eat and drink. Every 14 days you change the aligners and start the next step. Each aligner is custom made.

Reveal Your Smile

The Dent2Design Denture System features an innovative monolithic disc that integrates both tooth and denture base materials. This advanced technology allows for the seamless fabrication of fully customized complete dentures in a single milling process, requiring only polishing for the final touch

Scanning

→Perform a 3D Scan of Your Patient and Send Us The Scan File

Design

→We Do Design of Your Digital Denture

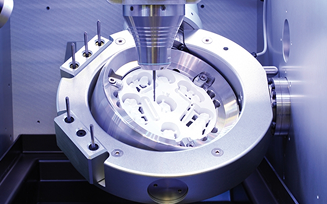

Milling

→We Do Digital Milling By The Only Ivotion Ivoclar Denture Milling Machine in GCC

Explore Our Craftsmanship

Discover the precision and innovation behind Dent2Design. From high-quality dentures to advanced digital solutions, our expertise ensures durability, aesthetics, and perfect customization for every smile.

A New Era OF Digital Smile/ Dentures

Step into the future of dentures with our digital process. Every minute detail of your smile is captured and stored with extreme precision, eliminating the stress of easy impressions. Best of all? We stand by our 'Perfect Fit Promise' and will adjust your dentures until you are completely satisfied with the look and feel, ensuring your confidence is restored.

Your Benefits Using Dent2Design

The Reliable Partner At Your Fingertips

- More flexibility in the manufacture of CAD/CAM restoration

- Higher productivity

- Optimal production planning

- High quality Comprehensive offering of materials

Outsourcing Partner For Every Lab

- Dent2Design Backup Reliable manufacturing services in the case of maintenance work

- Dent2Design Production More opportunities for using CAD/CAM

- Dent2Design Design & Production Easy entry into digital dentistry

Dent 2 Design

provides you with easy access to the world of dental CAD/CAM. Take advantage of our scanning, design and milling services. Forward your designs in STL format, choose from our comprehensive offering of materials and restoration options; e.g. use Service+ as a back-up service for your PrograMill unit in the case of maintenance work. Our production portfolio includes fixed, removable and implant prosthetics. Everything is possible.

CAD/CAM

The manufacturing industry has utilized computer-aided design (CAD) and computer-aided manufacturing (CAM) for decades to create precision tools and parts. Dent2Design is here to offer you both CAD and CAM services. At the moment we are supporting our clients with CAD

More Opportunities For Using CAD/CAM

Are you already using your own scanner and design software programs from 3Shape, DWOS or Exocad? If so, take advantage of our comprehensive offering of materials and numerous restoration types for fixed, removable and implant-supported prosthetics. We will do the milling for your lab: enhance the economic efficiency of your own production facilities by having e.g. complex restorations manufactured with the help of Dent2Design.

Crafting Excellence For DentalZorg

Crafting Excellence for DentalZorg At Dent2Design, we are honoured in our collaboration with DentalZorg, a renowned Dutch dental clinic. With a commitment to precision and quality, we design and manufacture high-performance dentures customized according to patient needs. Using cutting-edge digital technology and premium materials, we ensure:

Using Cutting-Edge Digital Technology And Premium Materials, WeEnsure:

- Seamless fit & superior aesthetics

- Durable, long-lasting restoration (8x stronger than conventional dentures)

- Advanced CAD/CAM fabrication

- Easily reproducible

Dent2Design and DentalZorg are redefining the future of dental art, delivering comfort, functionality, and confidence in every smile.

Our Successful Stories Of B2B Clients

Discover inspiring stories of recovery and healing from those we've had the privilege to serve.

We do the work, you get the benefit:

- Extended portfolio of materials and types of restorations

- Ideal capacity utilization of your own CAD/CAM equipment

- Good suction effect

- High quality standards

- For all open STL data formats